1. Mold design and production technology combination

Most CHINA rubber products company's mold outsourcing, customers provide drawings, rubber companies pass the drawing mold company. However, the process of the diaphragm is rather special. At present, the flow of our company is: the customer sends the product drawing, and we make the 3D mold drawing according to our own production technology and send it to the mold company. The mold company produces according to our requirements.

2. Constantly thinking about the automation of diaphragm production

Diaphragm production process is special, usually inside the product there will be cloth, iron, or other reinforcing materials, the old production process is very inefficient. At present, the labor force increases rapidly, so it is necessary to change the production of the diaphragm into automatic or semi-automatic. Currently in production of the product, we can use semi-automatic production.

3 like to touch difficult products

Difficult products on behalf of more high-end technology, is the future direction of development.

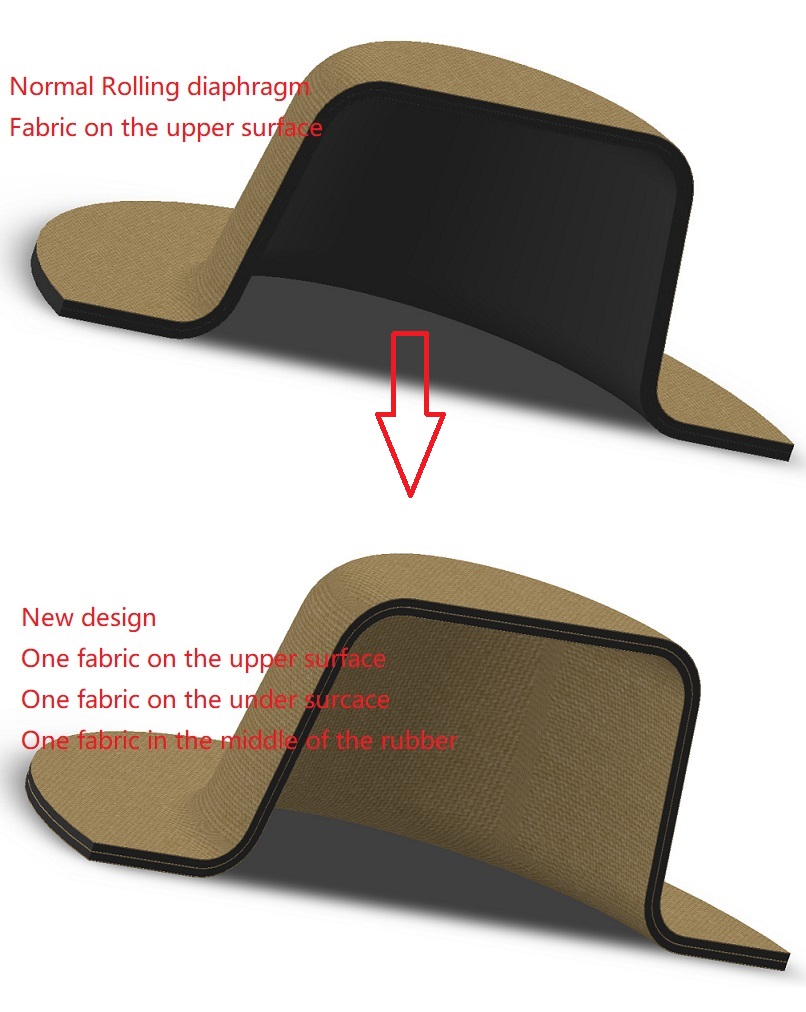

Currently we are developing a three-layer fabric products, mainly for air compressors and start-up equipment.

This is a product we imagine ourselves, no customer asked us to produce.

Just think of such a diaphragm in terms of wear resistance, pressure, and life expectancy will greatly increase.The follow Drawing can show our design.