GENERAL SEALTECH LIMITED a rubber diaphragm manufacture.We offer paid technology transfer, cooperation and support on Diaphragm production.

We have a systematic production technology and process, from mold design, to the selection of raw materials, to the production process. Currently we are in the process of semi-automatic design of diaphragm production (feeding and curing process), we can save 60% of the workforce, and the quality can be controlled better.

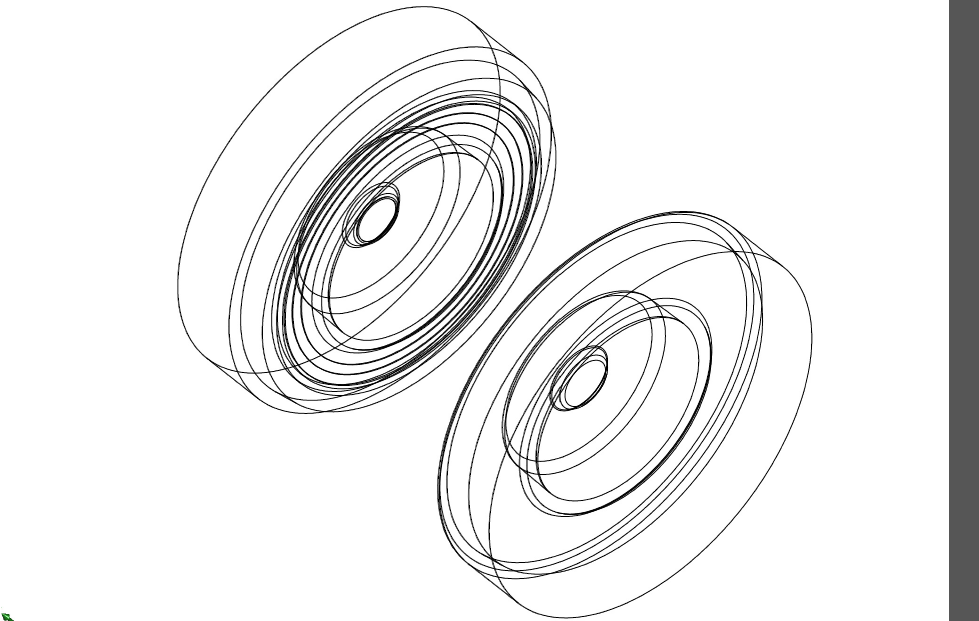

1.Mold design.

If you have 2D Drawing(CAD) or 3D Drawing(IGS), Mold design may take about 1 hour to complete.

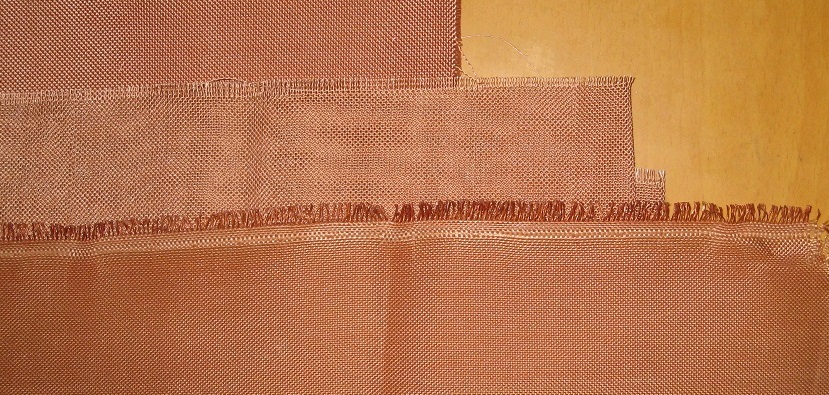

2.Raw material choose

Blended rubber, Fabric, Glue and other material, We have a clear list.

3.Semi-finished preparation

It is important for a Diaphragm quality

4.Curing process(vulcanization)

300 seconds for one diaphragm(Single-mode cavity). 1 employee manages 4 machines(quantity production)

4.Hole Punching and checking

Punching hole in Punching machine, Economical and fast

Mounting hole distance tolerance ±0.5,Hole diameter tolerance in ±0.2.